The Axis Electronics test team have all the skills and experience in house to develop a complete test strategy, selecting the most appropriate mix from:

- Automated Optical Inspection (AOI)

- Automated XRAY Inspection (AXI)

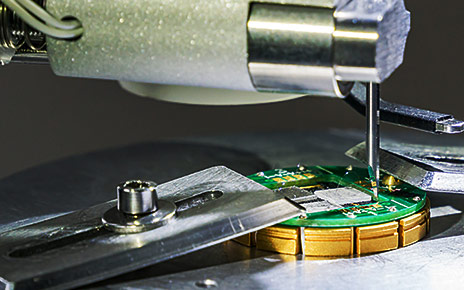

- Flying Probe

- Boundary Scan (JTAG Test)

- Device programming

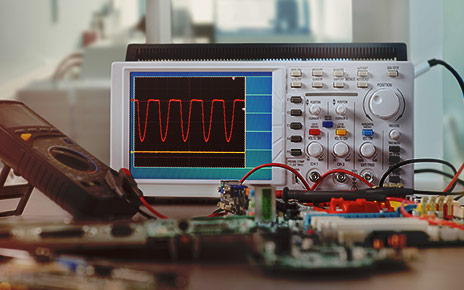

- Functional test

We have invested significantly in the test area including a dedicated area for JTAG, Labview and Test Stand development and have a wide range of experience in test automation and instrument control. Our wide range of test skills and resources include:

- Automation using LabVIEW and Test Stand over interfaces including PXI, Ethernet and GPIB

- JTAG and XJTAG program development

- RF Test capabilities

- High voltage (HV) Testing

- High Speed Digital Testing

- System Test and Product End of Line Configuration

- On / off board programming of electronically programmable devices

- Siemens Test Expert CAM tools to aid diagnosis

Axis Electronics is a complete test solution provider, from formulating a customer’s test strategy during New Product Introduction (NPI) phase, through to developing the most appropriate and cost effective working test system. If it is a PCB assembly test or a full suite of tests, including a system test and end of line product configuration, Axis Electronics has a team of engineers that have the skills and experience to design and implement the best solution.

Using a methodology of ‘complementary’ testing we work to maximize test coverage by the utilization of all the appropriate test resources, to budget, to ensure only a reliable product, suitably tested for its working environment is delivered to you and your customers.

From in process verification, production test development and Environmental Screening we have a wide range of solutions suited to low to medium volume, high reliability applications.